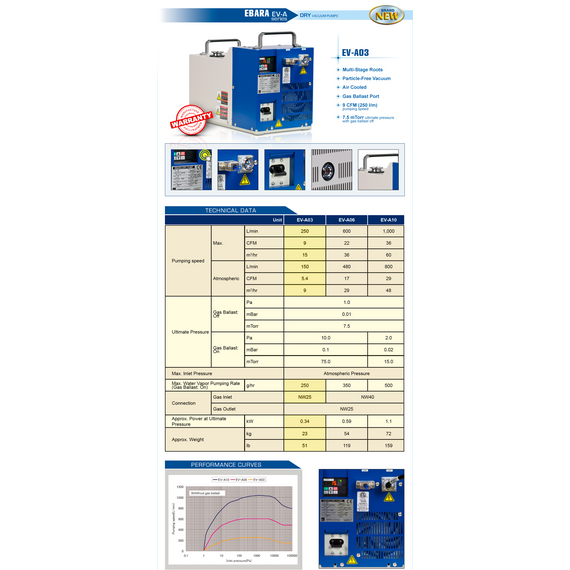

Ebara EV-A03-3 Air Cooled Dry Vacuum Pump 208-240VAC, 3-Phase, 9cfm, Gas Ballast Port. PN: 202552

- — 12 months warranty

- — SMS notification

- — Return and exchange

- — Different payment methods

- — Best price

These Ebara EV-A 03 series dry rotary lobe vacuum pumps are air-cooled and are designed for light duty dry vacuum applications. The EV-A 03 pumps dry pumps have a large 9 cfm (250 L/Min) pumping speed, have KF-25 inlet and exhaust ports, operate very quiet at 56 dB (A) operating noise level, and have an ultimate pressure without gas ballast of is 7.5 mTorr (75 mTorr with gas ballast on). Save money with low operating power consumption, as low as 1.1 kW at ultimate pressure. This unit has Ebara reference number EV-A03-3 which includes standard accessories, such as, the vertical exhaust orientation, external silencer & built-in check valve, operates on 3-phase 200-240 VAC, and port for optional gas ballast, having Ebara model EV-A03-3 and part number 202552.

The Ebara EVA 03 dry pumps employee multi-stage Roots roughing pump technology to achieve a totally clean dry vacuum, includes 6 internal pumping stages. The pump operates on a pair of hybrid Roots which synchronously rotate to keeping a given clearance while transferring the gas from the inlet to the outlet exhaust port. Gears are installed on the other side of the rotors where lubricating oil is used. These are dry vacuum pumps, the oil is not inside the vacuum volume of the pump and is only located inside the gear section. The EV-A 03 and EV-A 06 models use mineral gear oil while the EV-A 10 models use Fomblin PFPE gear oil.

The Ebara EV-A pumps produce a clean dry vacuum thanks to its frictionless design, being non-contact, multi-stage roots, reliable, and providing particle-free vacuum generation. Unlike scroll pumps, the EV-A pumps do not have tip seals that wear and generate particulate dust that can be a contaminant of the roughing line and processes chamber during suckback issues. The highly reliable design of the Ebara EV-A vacuum pumps allow for dry vacuum at lower cost of ownership. These pumps eliminate the hassle of tip seal & bearing replacements and do not have base pressure drifts that occurs as tips seals wear in dry scroll pumps. The improved rotary lobes pump design provides a constant ultimate pressure over the entire life of the pump, 7 mTorr base pressure.

The Ebara EV-A pumps are fan cooled but are designed to run at higher internal temperatures which allows them to have a large condensable vapor pumping capacity, 250 grams per of water per hour for the EV-A 03 models. Friction from the shaft seals and bearings along with heat that is generated as the gas is compressed help to increase the internal operating temperature of the vacuum pump. When pumping of condensable vapors, installation of the optional gas ballast is required, to prevent condensation inside the pump. Air or nitrogen introduced by the gas ballast reduces the partial pressure of the pumped gases to exceed their saturation vapor pressure (keep them in the vapor phase). It is recommended to use the atmospheric air gas ballast when pumping of non-flammable vapor and condensable solvents. When pumping gas vapors of flammable solvents the N2 ballast must be correctly used following the operation manual. It is effective to keep the pump running about one hour after process completion with the gas ballast valve open when pumping condensable gases like water vapor. This helps to remove all traces of water before the pump is turned off.

A major improvement in the Ebara EV-A design is that the first vacuum stage is located in the second position on the rotor. This orientation of the pumping stage design prevents the rotor bearings from being exposed to the high vacuum which will increase their operating life. The improved pump design also includes hard anodized aluminum body, stainless steel rotors, and internal exhaust check valves, features which help the Ebara EV-A pumps handle pumping of condensable vapors. The optional gas ballast is designed to injecting to the 3 and 4 stages in an optimal positions to increase the pumps vapor handling capacity while limiting its effect on the pumps base pressure. The robust design of the Ebara EV-A pumps offer a service life which is typically 3 to 5 years depending on the application and how the pumps are used.

The Ebara EV-A dry rotary lobe vacuum pumps include an operation panel and LED display to adjust the pump conditions and control pump settings, such as, run frequency, current, run hours, and error monitoring. These pump motors include a Variable Frequency Drive (VFD) that starts the pump slowly from rest to full speed, reducing noise and vibration, while providing a low start up current. The pumps also include an I/O connector D-sub port which provides dry contactor functions like remote start and alarm status monitoring.

The Ebara EV-A 03 series dry vacuum pumps are simple to use, simply plug them in and turn them on (it's that simple). They can be ordered to operate on 1-phase 115, 1-phase 208 VAC, or 3-phase 208 VAC, the current part number being sold here, 202552 is for the 3-phase 200-240 VAC pump. The Ebara EV-A pumps can operate continuously at atmospheric pressure without over heating or locking up. The Ebara EV-A vacuum pumps are compact and are quite during operation <56dB(A). Optional rolling casters are available for easy moving about the facility. Please see the additional information in the user's manual and products brochure downloads below.

- Benefits and Features of the Ebara EV-A series dry rotary lobe pumps.

- Air-Cooled

- Small, Compact Size

- Non-Contact Design

- Constant Ultimate Pressure

- No Production of Tip Seal Dust

- High Atmospheric Pumping Speeds

- CE and NRTL rated

- Single-Phase and Three-Phase Models Available

- Low Vibration

- Low Noise

- Maintenance Free

- Highest Water Vapor Pumping of Any Air Cooled Dry Pump (with gas ballast open)

- Applications

- Load Lock

- Analytical Instruments (LCMS Liquid Chromatography–Mass Spectrometry, GCMS Gas Chromatography Mass Spectrometry)

- Metrology - SEM (Scanning Electron Microscopes), TEM (Transmission Electron Microscopy)

- PVD (Physical Vapor Deposition) Sputter Systems

- Drying Vacuum Ovens

- Oxygen Plasma Systems

- Wet Pump Replacement

- Scroll Pump Replacement

- Clean Application

- Glove Boxes

- Lyophilization (Freeze Drying)

- Sterilizers (Vaporized Hydrogen Peroxide Sterilizer medical devices Vacuum Steam Sterilization for Hospital Applications).

- Leak Detectors

- Beam Line & Synchrotrons

- High Energy Physics (Research & Development Laboratories – R&D)

- Space Simulation Chambers

- Turbo Pump Backing

- Flexible LED Video Display Manufacturing

- Absolutely Clean & Dry Vacuum for Medical Devices & PCB Board Manufacturing

- Medium Duty, compete with PFPE Rotary Vane Pumps, Pumping Oxygen Applications. Plasma O2 CF4

No reviews found